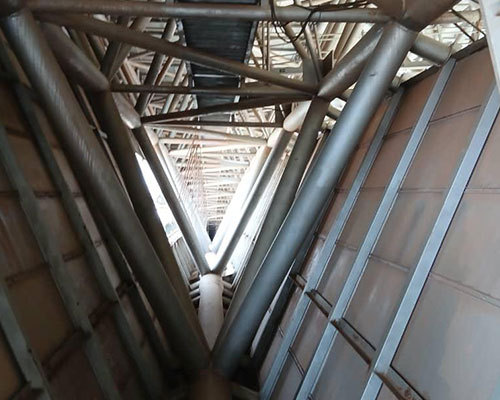

Outdoor Stadium Steel Truss Roof Long-Span Tubular Truss Structure Custom Design Fabrication Installation

Item specifics

- Type

- Space Frame Truss/Triangular Truss/Truss

- Steel Grade

- Q355GJC / Q460C (GB/T 19879)

- Steel Pipe Standard

- GB/T 8162-2018

- Corrosion Protection

- Thermal Spray Aluminum (≥150μm) + Fluorocarbon T

- Joint Load Capacity

- ≥1500 kN (Cast Steel Joints)

- Deflection Control

- ≤1/400 of the span

- Wind Load Resistance

- ≥1.5 kN/m² (50-year recurrence interval)

Review

Description

Quick Details

LARGE-SPAN TRUSS ROOF SYSTEM

A truss is a lattice structure composed of members connected at joints within a plane. It utilizes the geometric stability of triangular units to convert external forces into axial forces (tension or compression) within the members, allowing for large spans with minimal material use.

-These project photos were provided by our partner GZZHCE.

ITEM | PARAMETER |

Steel Grade | Q355GJC / Q460C (GB/T 19879) |

Steel Pipe Standard | GB/T 8162-2018 |

Corrosion Protection | Thermal Spray Aluminum (≥150μm) + Fluorocarbon Topcoat |

MECHANICAL PERFORMANCE | |

Joint Load Capacity | ≥1500 kN (Cast Steel Joints) |

Deflection Control | ≤1/400 of the span |

Wind Load Resistance | ≥1.5 kN/m² (50-year recurrence interval) |

INSPECTION & CERTIFICATION | |

Certified under CE / ISO 3834 Welding System | |

Includes third-party weld inspection reports (UT/RT testing) | |

Application Scenarios | |

Main arenas of multi-purpose sports stadiums, Athletics halls / Speed skating arenas, Large-scale performance venues | |

TYPE OF SPACE GRID STRUCTURE

Space Frame Truss

Uses circular or square tubes with intersecting welds.

Three-dimensional force distribution for high efficiency and stability, with a modern aesthetic.

Ideal for large-span spatial structures.

Triangular Truss

Triangular grid with excellent geometric stability.

Classic and robust design; simple to design and construct.

One of the most widely used truss types.

Arch Truss

Curved top chord for optimal force distribution.

Material-efficient and suitable for long spans.

Elegant in form, combining both aesthetics and functionality.

CORE ADVANTAGES OF SPACE GRID STRUCTURES

Ultra-Large Span

Single spans can exceed 200 meters.

Tubular truss structures offer high rigidity, making them ideal for extremely large and heavy roof systems.

Cost-Effective

Saves 15–20% more steel compared to space frames.

Trusses are composed of linear elements, often requiring less steel, making them a more economical choice.

Fast Construction

Segmental lifting reduces construction time by 30%.

Trusses are typically prefabricated in large segments at the factory and lifted into place on-site, minimizing on-site work and reducing the number of lifts required.

Versatile Forms

Supports straight, arched, and fish-belly shapes.

Tubular trusses are especially suited for smooth, large-radius curves such as arches or saddle shapes. The fish-belly form features a curved bottom chord, offering both structural efficiency and aesthetic appeal.

Supply Capacity

Design Capability

Design capability is the core prerequisite for supply capacity and serves as the endorsement of technical feasibility.

Maximum Design Span: 250 meters (validated by finite element analysis)

Seismic Resistance: Designed to meet Seismic Intensity 9 (GB50011-2010)

Manufacturing Capability

Manufacturing capacity is the solid foundation of our supply capabilities.

| ITEM | PARAMETER | ||

| Annual Production Capacity | 300,000 m² of truss structures | ||

| Main Material Specs | Ø100–Ø800 mm steel pipes / box beams | ||

| Joint Types | Intersecting joints / Cast steel joints / Flange connections | ||

Delivery & Support

Design Phase

ANSYS structural analysis report provided.

Detailed joint drawings (including welding procedure qualification).

Construction Phase

500-ton crane team (100% certified operators)

Total station positioning installation (tolerance ≤5mm)

Quality Assurance System

Designed service life of the main structure: 50 years

Truss Structure Health Monitoring Plan provided

Specialized Solutions

| Composite Systems | Innovative Technologies | |||||

| Truss + Metal Roofing (Basic Type) | + | Intelligent Pre-Cambering Technology (to offset load-induced deformation) | ||||

| Truss + Glass Skylight (Translucent Type) | Local Reinforcement with Fiber-Reinforced Polymer (FRP) | |||||

| Truss + Retractable Mechanism (Movable Roof) | ||||||